Precision In Every Dimension: Exploring Alignment Cubes In Micro-Nano Optics

The Importance of Alignment in Optical Systems

Precision alignment is critical in optical systems because even microscopic deviations can lead to errors in performance. Studies show that in high-precision optical applications, misalignment as small as 5 micrometers (µm) can cause a 20% loss in system efficiency. This is particularly crucial in laser systems, fiber optics, and imaging technologies where beam path stability directly affects results.

Alignment cubes serve as reference structures that help ensure all optical elements are positioned correctly. These components are widely used in industries that demand extreme accuracy, such as:

- Telecommunications: Ensuring precise alignment in fiber optic networks to reduce signal loss.

- Semiconductor Manufacturing: Improving accuracy in photolithography and wafer inspection systems.

- Biomedical Imaging: Enhancing the precision of optical coherence tomography (OCT) and other imaging technologies.

- Aerospace and Defense: Maintaining optical stability in laser guidance and targeting systems.

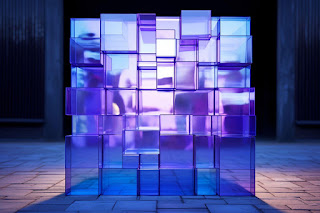

What Makes Alignment Cubes Unique?

Alignment cubes are engineered to maintain high dimensional stability, often featuring properties such as:

- Ultra-High Precision: Manufactured with tolerances as tight as ±1 arcsecond to ensure minimal deviation.

- Material Stability: Typically made from fused silica, BK7 glass, or optical-grade ceramics for durability and minimal thermal expansion.

- Anti-Reflective and Coated Surfaces: To minimize optical losses and enhance performance in laser applications.

Compared to traditional alignment techniques, these cubes provide superior stability and ease of integration, making them essential for high-performance optical setups.

How Alignment Cubes Work in Micro-Nano Optics

Micro-nano optics deals with optical structures at scales ranging from a few micrometers to nanometers. Given the complexity and precision required at these levels, alignment cubes play a crucial role in ensuring that light follows the intended path without deviation.

1. Beam Steering and Reflection

Alignment cubes often incorporate precision mirrors and beam splitters to control and direct light. In interferometry, for instance, they are used to split a laser beam into two paths, allowing for highly sensitive measurements of surface profiles and wavefront distortions.

2. Fiber Optic Coupling

In fiber optic systems, alignment cubes are used to position fibers with sub-micrometer accuracy, ensuring maximum transmission efficiency. Studies show that improper alignment can reduce fiber coupling efficiency by 30-50%, significantly affecting signal quality.

3. Microscopy and Imaging Systems

Biomedical and industrial imaging systems rely on alignment cubes to stabilize optical components and prevent distortions. In applications such as confocal microscopy and fluorescence imaging, proper alignment ensures clear, high-resolution images.

The Growing Market for Precision Optics

The demand for high-precision optical components, including alignment cubes, is rapidly increasing. According to market research, the global precision optics industry is expected to grow at a CAGR of 7.2% from 2023 to 2030, driven by advancements in semiconductor technology, medical imaging, and space exploration.

- The fiber optics market alone is projected to reach $11.2 billion by 2026, emphasizing the need for precise optical alignment.

- Laser-based manufacturing systems are expected to grow by 8.5% annually, further driving demand for precision optics.

- Biomedical imaging devices utilizing micro-nano optics are forecasted to be a $60 billion industry by 2030, highlighting the crucial role of alignment cubes in future medical technologies.

Future Innovations in Alignment Cubes

As optical technologies continue to evolve, alignment cubes are also advancing to meet the increasing demand for precision and miniaturization. Future developments may include:

- Nano-Structured Coatings: To reduce reflection losses and improve optical efficiency.

- Smart Alignment Systems: Integration with AI and adaptive optics for self-correcting alignment in real-time.

- Enhanced Material Engineering: New materials with lower thermal expansion coefficients to improve stability in extreme environments.

Conclusion

Alignment cubes are vital in maintaining precision and accuracy in micro-nano optical systems. From telecommunications to biomedical imaging, their role in ensuring proper optical alignment cannot be overstated. As technology continues to advance, the demand for these components will only increase, driving innovation in precision optics. With new materials, smart alignment systems, and enhanced coatings on the horizon, alignment cubes will remain at the forefront of optical engineering, enabling groundbreaking advancements across industries.