Single Sided Flex PCB: PCB Component Sourcing Made Easy with FastTurnPCB

Efficient PCB component sourcing is a critical factor in modern electronics manufacturing. Ensuring that every component meets quality, compatibility, and availability standards can dramatically impact the success of your project. For companies designing flexible electronics, choosing a reliable partner for both PCB fabrication and component sourcing is essential. FastTurn PCB simplifies this process, providing high-quality single sided flex PCB solutions alongside comprehensive sourcing, assembly, and testing services to streamline production and accelerate time-to-market.

The Importance of PCB Component Sourcing

Sourcing components for PCB production is more than just procurement; it involves:

- Ensuring the right specifications, tolerances, and quality

- Verifying compatibility with PCB design and layout

- Managing lead times and availability to meet production schedules

- Reducing costs through efficient supply chain management

Poor component sourcing can lead to production delays, design failures, and higher costs. Partnering with an experienced provider like FastTurn PCB ensures that all components are sourced reliably, tested for quality, and integrated seamlessly into the final PCB assembly.

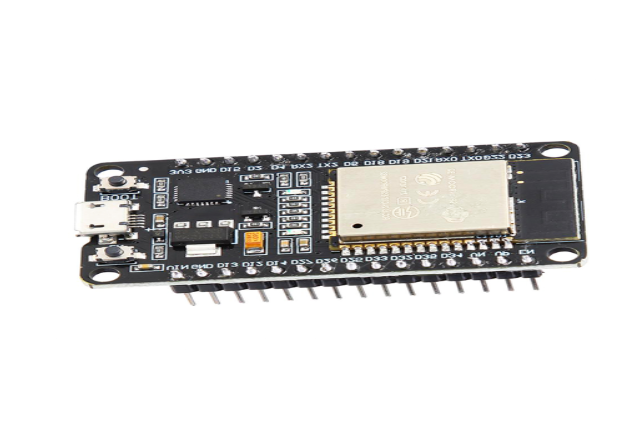

FastTurn PCB: Your Single Sided Flex PCB Partner

FastTurn PCB is a trusted provider of single sided flex pcb fabrication and component sourcing services. Their integrated approach combines PCB manufacturing, component procurement, and turnkey assembly, delivering end-to-end solutions for a variety of industries.

Key Advantages of FastTurn PCB Component Sourcing

- Reliable Component Availability

FastTurn PCB maintains partnerships with trusted suppliers to source high-quality components that meet stringent industry standards. This ensures on-time delivery and eliminates supply chain bottlenecks. - Expertise in Single Sided Flex PCB Design

Single sided flex PCBs are widely used in applications requiring flexibility, lightweight construction, and cost efficiency. FastTurn PCB’s engineers ensure that components are correctly selected and placed to maximize performance and durability. - Turnkey Assembly Services

In addition to sourcing, FastTurn PCB provides full turnkey assembly services, including:- SMT and through-hole assembly

- BGA placement and inspection

- Functional testing and quality control

This integrated approach ensures that components are correctly installed, tested, and ready for deployment.

- Quality Assurance

Every component sourced and assembled is subject to rigorous quality inspections, including:- Electrical testing to ensure performance

- Visual inspection for defects or misalignment

- Compliance with ISO 9001, UL, and RoHS standards

- Rapid Turnaround

With FastTurn PCB’s efficient sourcing and assembly processes, prototypes and production orders can be delivered within 24–72 hours, helping clients accelerate product development cycles.

Applications of Single Sided Flex PCBs

Single sided flex PCBs are widely used in industries where compact, lightweight, and flexible designs are required. Key applications include:

- Consumer Electronics: Wearables, fitness trackers, smart home devices, and mobile accessories

- Medical Devices: Portable diagnostic tools, wearable monitors, and patient tracking electronics

- Automotive Electronics: Flexible circuits for sensors, lighting, and control systems

- Industrial Automation: Flexible PCBs for robotics, sensors, and machinery controls

- Telecommunications: Compact circuits for networking and communication devices

By combining high-quality single sided flex PCB fabrication with efficient component sourcing, FastTurn PCB helps manufacturers reduce errors, improve reliability, and accelerate time-to-market.

How FastTurn PCB Streamlines Component Sourcing

FastTurn PCB simplifies PCB component sourcing by offering:

1. Centralized Supply Chain Management

Instead of managing multiple suppliers, FastTurn PCB provides a centralized sourcing solution. This reduces complexity, minimizes errors, and ensures that all components are fully compatible with the PCB design.

2. Access to High-Quality Components

FastTurn PCB works with trusted suppliers worldwide to source premium-quality components that meet rigorous performance and compliance standards. This ensures long-lasting and reliable PCBs for end-users.

3. Cost Optimization

Bulk purchasing and strategic supplier partnerships allow FastTurn PCB to optimize costs, providing clients with competitive pricing without sacrificing quality.

4. Integrated Testing and Verification

All sourced components are tested and verified as part of the assembly process. This includes electrical testing, visual inspection, and functional validation, ensuring that every single sided flex PCB is fully functional and reliable.

5. Flexible Production Volumes

FastTurn PCB accommodates small-batch prototypes and large-scale production runs, allowing clients to scale efficiently without worrying about component shortages or assembly delays.

Benefits of Partnering with FastTurn PCB

Choosing FastTurn PCB for single sided flex PCB fabrication and component sourcing offers numerous benefits:

- Speed: Rapid prototyping and sourcing help accelerate product development

- Reliability: Trusted suppliers and strict quality control ensure dependable performance

- Expertise: Engineers optimize component selection and PCB layout for maximum performance

- Cost Savings: Efficient sourcing, assembly, and quality management reduce overall project costs

- Global Reach: Serving clients worldwide with consistent service and delivery

These advantages make FastTurn PCB the ideal partner for startups, OEMs, and electronics manufacturers seeking efficient, high-quality PCB solutions.

Innovations Driving FastTurn PCB

FastTurn PCB continually invests in advanced technologies to enhance PCB fabrication and component sourcing:

- Automated assembly lines for precise and efficient placement

- Advanced testing systems for electrical, functional, and reliability checks

- Environmentally compliant processes meeting RoHS and REACH standards

- Flexible PCB design innovations to accommodate compact, bendable, and foldable electronics

By leveraging these innovations, FastTurn PCB ensures that clients receive single sided flex PCBs that are reliable, high-performing, and ready for immediate use.

Customer Success Stories

Clients across multiple industries rely on FastTurn PCB for flexible PCB fabrication and component sourcing. For example, a wearable device company required a single sided flex PCB with rapid component procurement and assembly. FastTurn PCB delivered the fully assembled prototypes within 48 hours, allowing the client to test, refine, and finalize their design ahead of schedule.

Such success stories demonstrate FastTurn PCB’s expertise, speed, and reliability, making them a trusted partner for electronics manufacturers worldwide.

Conclusion

Effective PCB component sourcing is crucial for efficient production, cost management, and timely delivery in the electronics industry. By partnering with FastTurn PCB, manufacturers gain access to high-quality single sided flex PCB fabrication, comprehensive component sourcing, turnkey assembly, and rigorous quality control.

With FastTurn PCB, clients benefit from fast turnaround times, reliable components, and fully tested PCBs, empowering them to bring innovative electronics products to market with confidence.

Simplify your PCB production and experience the difference of working with a professional, reliable partner: